Sales product

5.1. Definition

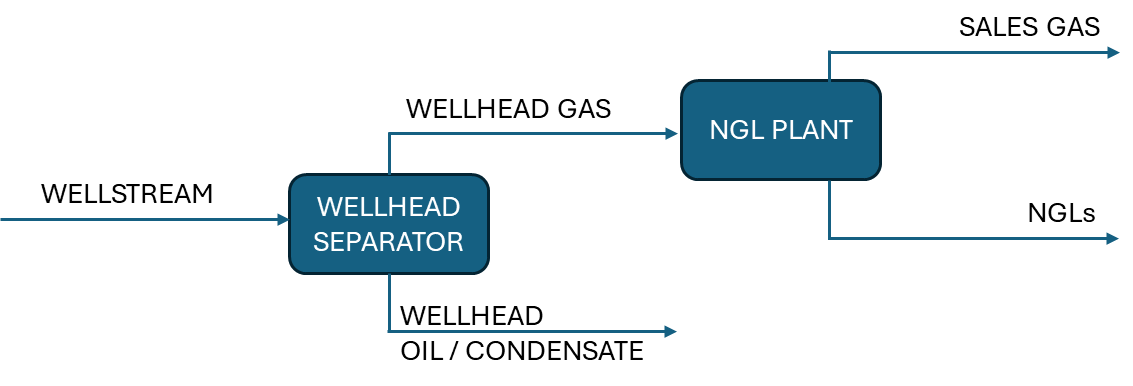

Wellhead Gas

- The gas coming out of the separator at the wellhead and entering the NGL plant.

- This is the actual gas stream processed for NGL extraction.

Sales Gas

- The final gas product after the NGL plant.

- Stripped of heavier hydrocarbons (NGLs), making it drier and pipeline-ready, i.e. sales gas.

Fat Gas (a.k.a. Wet Gas)

An artificially reported stream in some production databases. It basically recombines:

- Gas coming out of the separator (Wellhead Gas)

- Condensate from the separator (converted to gas-equivalent)

Important: this stream does not exists as a real gas stream but is mostly used for reporting, to track total hydrocarbon content as a single gas stream.

5.2. Natural Gas Liquids (NGL)

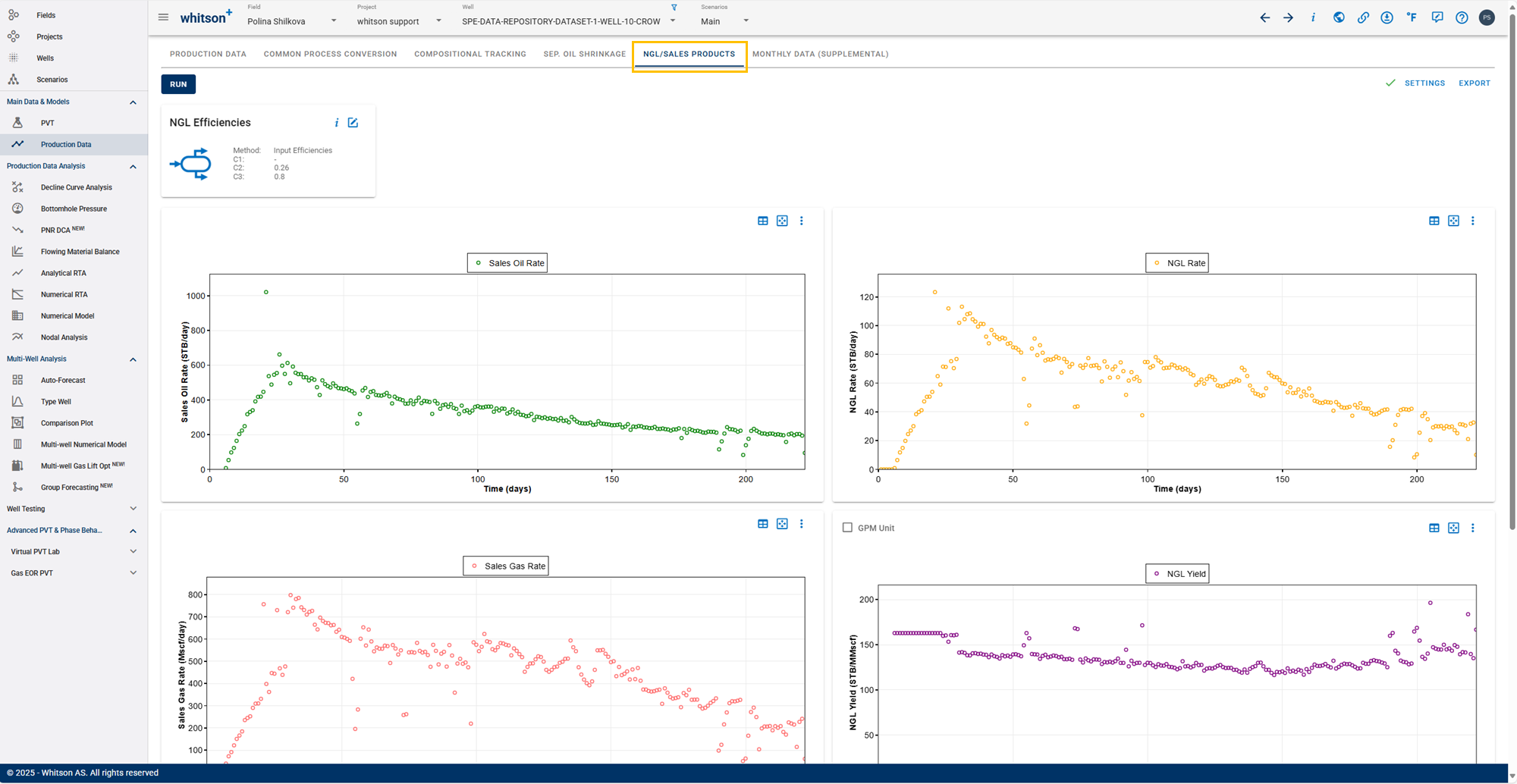

In this module, daily NGL rate (\(q_{NGL}\)) and NGL yield are predicted. The required input for the user is NGL efficiencies (\(e\)).

5.2.1. Recovery Method

The process of removing NGL's is acknowledged as NGL recovery. There are four methods to calculate NGL recovery available in whitson+:

- Dewpoint Control: controls hydrocarbon and water dew points of natural gas through mechanical refrigeration.

- Cascade Refrigeration: uses two refrigeration ciscuits thermally connected by a cascade condenser.

- Gas Sub-cooled Process (GSP) Deep Recovery: develops a source of reflux to increase \(C_2\) recovery with the conventional design.

- Input Efficiencies

Each method has a list of components according to the EOS model used. The default efficiencies for each method is given in Table 1. Using one of this default values is good for the starting point of the NGL efficiency, the values can be changed as desired.

| Component | Dewpoint Control | Cascade Refrigeration | GSP Deep Recovery | Input Efficiencies |

|---|---|---|---|---|

| \(N_2\) | 0 | 0 | 0 | 0 |

| \(CO_2\) | 0 | 1 | 1 | 0 |

| \(H_2S\) | 1 | 1 | 1 | 0 |

| \(C_1\) | 0 | 0 | 0 | 0 |

| \(C_2\) | 0.25 | 0.65 | 0.95 | 0.5 |

| \(C_3\) | 0.80 | 0.97 | 0.99 | 1 |

| \(C_4+\) | 0.97 | 1 | 1 | 1 |

5.2.2. Calculations

To predict the NGL yield and NGL rate correctly, the following inputs are fundamental:

- daily measured oil and gas rates (\(q_o\) and \(q_g\))

- daily gas moles (\(n_{gas}\))

- daily composition of surface gas (\(y_i\))

- NGL efficiencies (\(e\))

Gas and oil production rates are used to calculate \(n_{gas}\) and (\(y_i\)). In whitson+, \(n_{gas}\) and (\(y_i\)) are calculated in compositional tracking module.

Mole of NGL sales is written as:

Liquid phase mole fraction of each component can be defined

NGL molecular weight and specific gravity are expressed as follows

Finally, the NGL rates and thus NGL yield can be solved for each production day

The units of NGL rate is STB/d and NGL yield is STB/MMscf (or gallon per 1,000 cubic feet, GPM).

5.2.3. Ethane Rejection vs. Ethane Recovery

When demand for ethane, and therefore ethane prices, are low relative to dry natural gas prices, natural gas processing plant operators may choose to leave ethane in the processed natural gas (provided the processed natural gas meets pipeline specifications) and sell it into the natural gas market at its heat value. This process is known as ethane rejection.

When ethane prices rise higher than natural gas prices on a heat-value equivalent basis, natural gas processing plant operators may choose to recover the ethane along with other NGPLs and sell it at their market value into the petrochemical sector. This process is known as ethane recovery.

Most recovery units are built for both ethane recovery and ethane rejection, and when operated in ethane rejection mode the ethane recovery (NGL efficiency) is low (e.g. 40%), while when operated in ethane recovery mode the ethane recovery (NGL efficiency) is high (e.g. 90%).