Nodal Analysis - Gas Lift Optimizer

1. Overview

This module within the Nodal Analysis section is designed to optimize gas lift performance for maximizing oil production under specific surface/subsurface setups and operating conditions.

Traditionally, evaluating the effect of varying gas injection rates required manually saving multiple VLPs under different wellbore and surface configurations, then comparing their intersections with the IPR to identify optimal conditions. This feature simplifies that process by integrating all steps — IPR/VLP generation, gas lift rate variation, and case comparison—into one streamlined tool. The GIF below demonstrates this simplified approach:

Within this tool, you can:

- Set up inflow performance relationships (IPRs) for specific dates in the well’s history.

- Test sensitivities on wellhead pressures (tubing and casing), bottomhole pressure correlations, and wellbore configurations.

- Evaluate the effect of changing gas lift injection rates.

- Quantify the oil rate uplift potential and optimize gas injection strategies.

The goal is to provide actionable insights for maximizing return on injected gas — whether that means adjusting wellbore hardware, tuning injection strategies, or redesigning surface conditions.

2. Basics

To begin, an IPR must be created in the IPR/VLP section for a selected date in the well’s production history. VLPs are generated based on:

- Surface pressures (tubing and casing),

- Gas-Oil Ratio (GOR),

- Gas lift injection rates,

- Bottomhole pressure (BHP) correlations,

- Wellbore configurations.

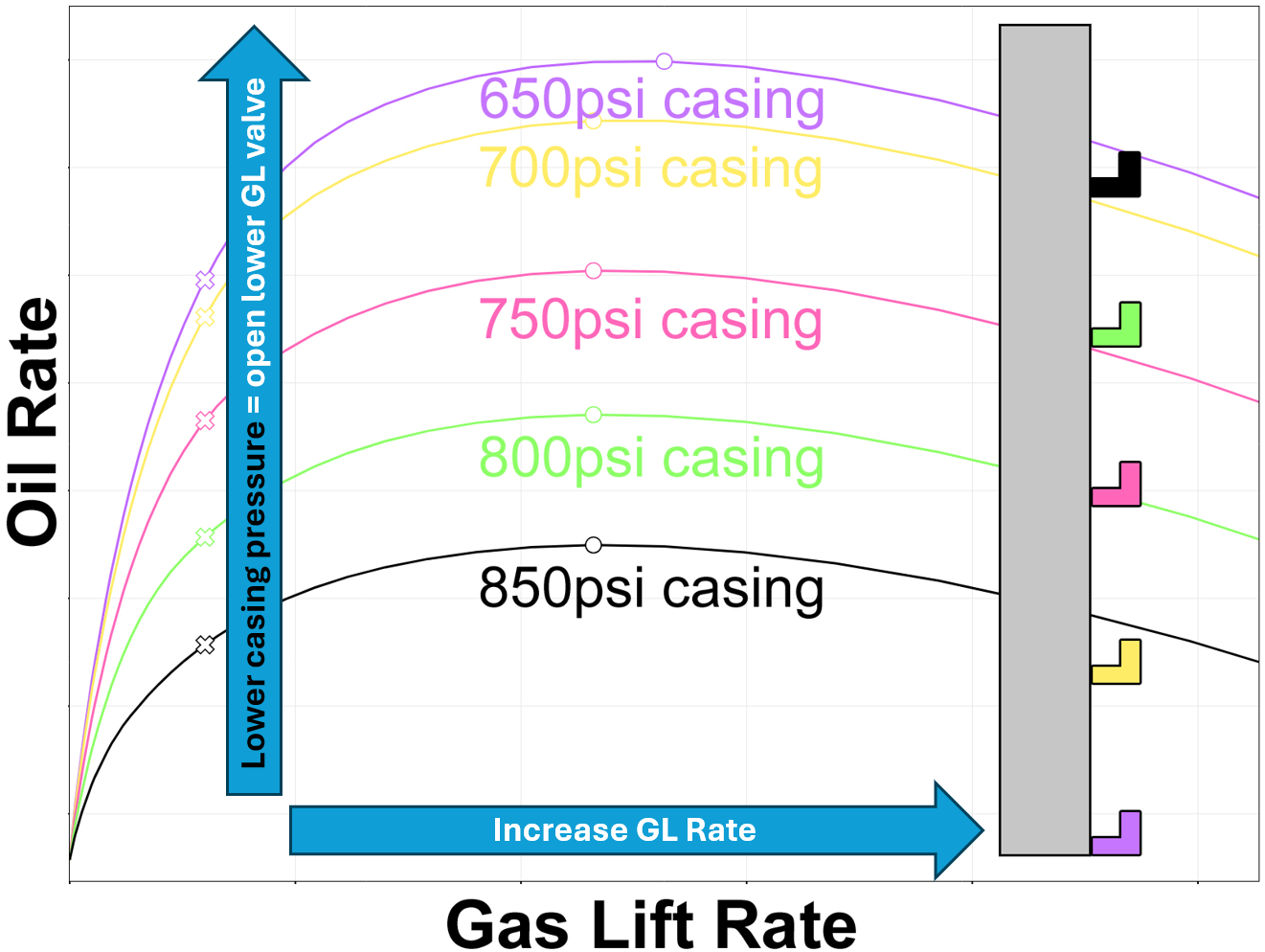

Each VLP that intersects the IPR represents an operating point (i.e., expected oil rate under specific conditions). By generating multiple VLPs for varying gas injection rates, a gas lift optimization curve is built—plotting oil rate against injection rate.

Typically, oil rate increases with gas injection until the added friction from excessive gas reduces the benefit. The optimization curve helps you identify:

- The current operating point,

- The maximum achievable oil rate,

- The required gas injection rate to reach that optimum.

These insights support decisions related to gas allocation, surface facility design, and economic planning.

2.1. Workflow

-

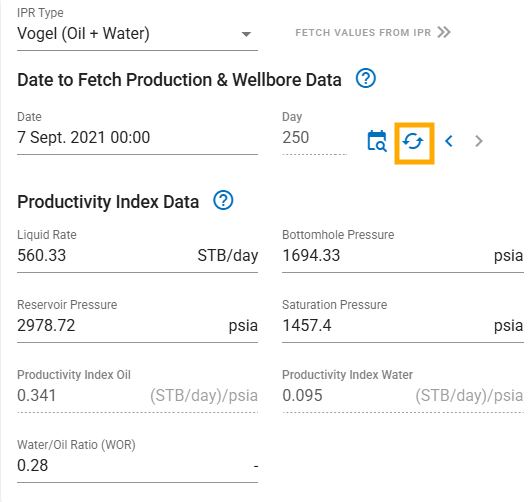

In the IPR/VLP section, select the date for IPR generation by clicking the calendar icon. You can manually enter the date and view the corresponding rates and pressures for the selected day. Additionally, you can fetch the reservoir pressure calculation from your preferred simulation, such as Multiphase FMB, Gas FMB, or History Matching, provided that these simulations have been previously completed.

-

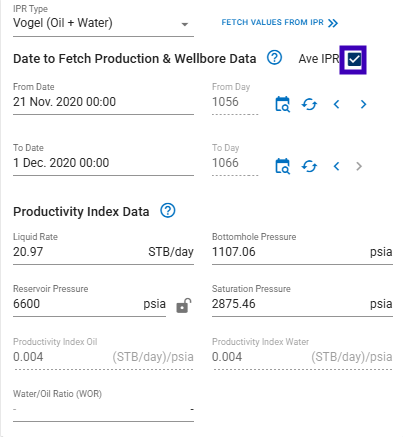

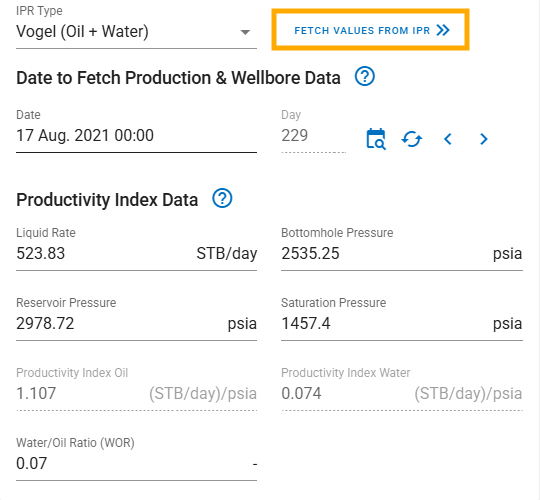

The current IPR and related input are loaded into the optimizer on first access. You can fetch the data from the selected date by clicking the refresh icon or you can manually input desired values into each field.

-

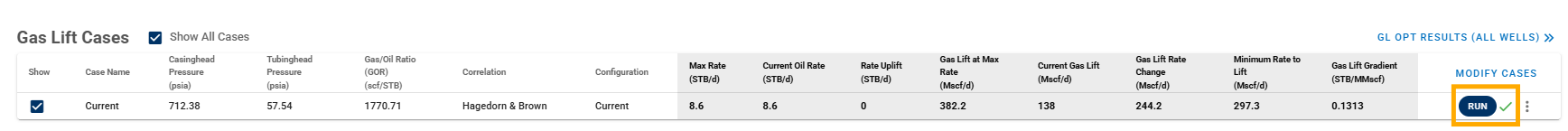

Use the MODIFY CASES button to create multiple sensitivity cases, varying:

- Wellhead pressures (CHP and THP)

- Gas-Oil Ratio (GOR)

- BHP correlation

- Wellbore configuration

-

Save and run the cases – optimization curves are generated automatically.

- Review optimization curves and summary tables for all cases.

2.2. Average IPR

Use an averaged IPR over a date window to smooth noisy daily data before running optimization. The optimizer will then use this representative IPR for all VLP cases.

- In IPR / VLP, select Average IPR and set the Start Date and End Date.

- Confirm streams and pressures, then generate the averaged IPR.

- Return to Gas Lift Optimizer and click Fetch values from IPR to load the averaged curve.

- Run or re-run your cases. The optimization curve will be based on the averaged IPR.

3. Case Comparisons

3.1. Varying Wellhead Pressures

This example compares different combinations of casing and tubing head pressures (CHP, THP). The base case reflects current operating conditions, while other cases simulate surface pressure changes.

In the example in section 2, a 129.4 STB/D rate uplift is achievable by increasing gas injection by ~900 Mscf/D. Alternatively, reducing THP to 14.7 psia achieves similar gains without increasing injection.

Impact of Surface Pressure on Gas Lift Optimization

Varying CHP may have no effect in single-valve systems, but in multi-valve wells, it changes the depth of gas entry—thus affecting optimization.

3.2. Varying BHP Correlations

Here, only the correlations used to compute the VLP are varied and you can see how VLPs from other correlations respond to the increasing gas injection rate. Each correlation produces a different response to gas injection.

For this well, Woldesemayat & Ghajar yields the best match with the IPR. It shows a potential uplift of 129.3 STB/D with an increase of ~900 Mscf/D gas.

3.3. Comparing Wellbore Configurations

This strictly requires that the alternative wellbore configurations used should be some form of gas lift. You can add or remove valves from the tubing, adjust valve depths, opening and closing pressures, and compute the gas lift optimization curve for alternate gas lift designs.

4. Multi-point Sampling for GLO

Select a more representative GLO case by minimizing the impact of outliers. A 10-day production history is used to visualize the range of possible optimization results and help identify the most consistent operating trend.

Show Additional Points on the Graph - You can display liquid rate and bottomhole pressure (BHP) points from other dates on the IPR/VLP graph. These points still originate from IPR/VLP calculations, but the plot will dynamically compute and display the gas lift optimization (GLO) results for the selected point. This allows you to compare GLO outcomes across different operating conditions using historical data. Selecting a point automatically updates the graph with the corresponding IPR/VLP inputs and shows the GLO result, making it easier to track changes in performance and assess optimization potential over time.

5. GLO Opt Results

The GLO Opt Results section in whitson+ is a centralized workspace for reviewing and comparing the outcomes of gas lift optimization cases. Users can evaluate multiple optimization scenarios derived from different wells side-by-side, such as pressures or gas lift rates, using intuitive comparison tools paired with a result table. Only the “current” optimization case for each well is shown in the table, and the values displayed are based on the date which the production data was fetched from. You can access the GLO Opt Results table from the Gas Lift Optimization section in the Nodal Analysis tab or from the Wells section by selecting "Results." The GIF below demonstrates this process.

6. Tips

6.1. IPR Selection

Finalize the IPR to be used in the IPR/VLP section. Then, in the Gas Lift Optimization tab, ensure the correct values are populated for creating the underlying IPR by clicking 'Fetch values from IPR'. Each time the IPR is updated, the cases will automatically re-run.

6.2. Running a Case

Each time a case is updated, it will run automatically and update the gas lift optimization curve. No need to re-run when directly modifying a case input. However, if the IPR changes, you must manually re-run each case to refresh the optimization results.

6.3. New Wellbore Configurations

You can also compare new wellbore configurations by clicking the Add/Edit Well Configuration button. From there, you can either copy the current configuration or build a completely new one from scratch. Be sure to give it a name and save it.

Once you return to the case inputs, use the Configuration dropdown to select your newly created configuration by its saved name.

Configuration Disclaimer

Configurations cannot be edited once saved. To make changes, you’ll need to create a new configuration from scratch.

6.4. Send to GLO Opt

You can export your VLP cases individually to the GLO tab by clicking the three dots, selecting the desired destination, and entering a name for the case.

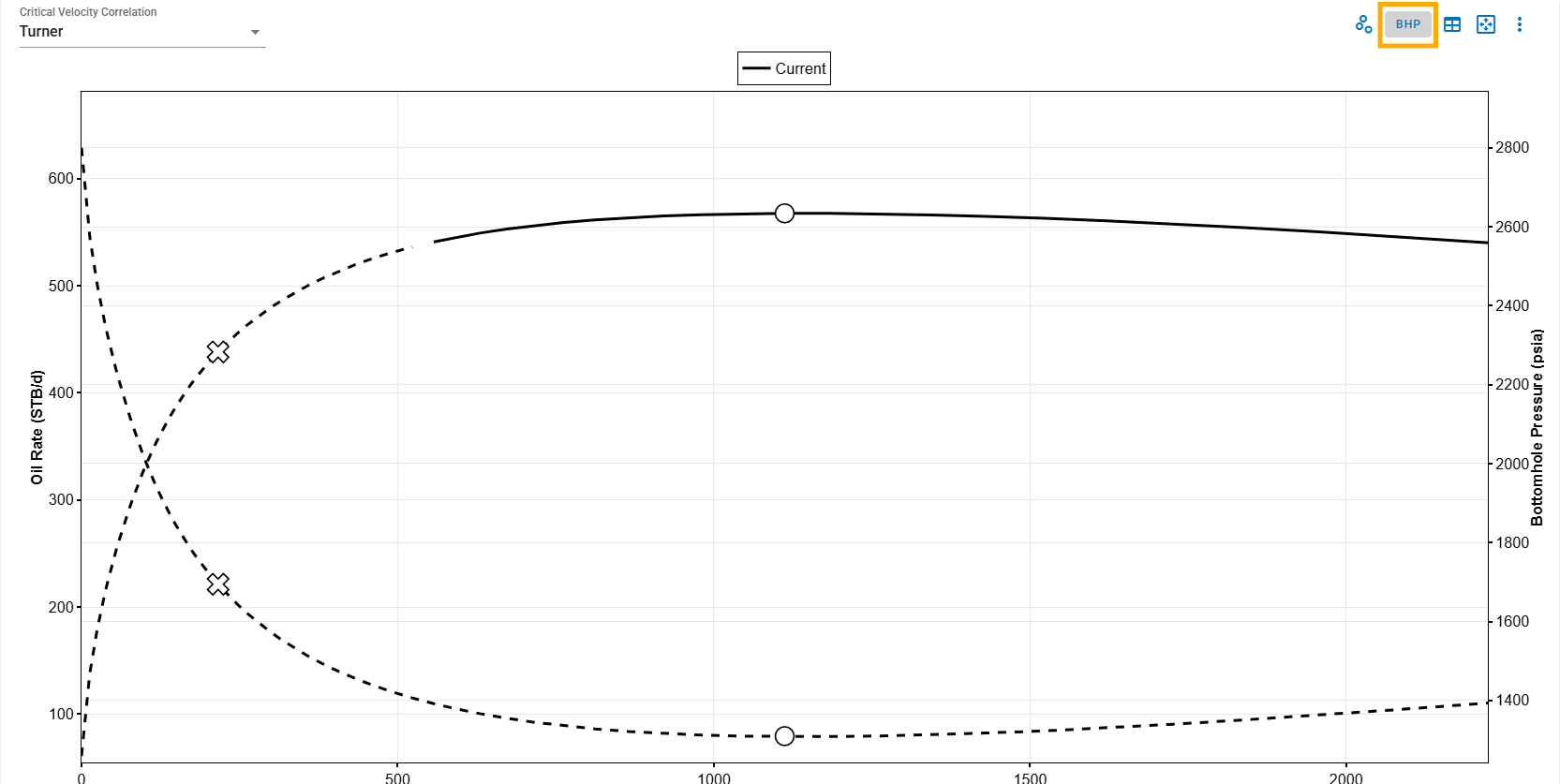

6.5 Plot BHP

You can also plot the BHP on the oil rate vs. gas lift injection rate graph to identify liquid loading conditions. This helps visualize how BHP responds to varying gas injection rates, indicating the minimum injection required to lift liquids and showing the maximum achievable oil rate along with the corresponding bottomhole pressure.