Multi-well Gas Lift Opt

1. Overview

The Multi-well Gas Lift Optimizer is designed to allocate limited lift gas resources across a group of wells to maximize total oil production. Rather than optimizing each well in isolation, this module considers the diminishing returns of injecting gas into individual wells and redistributes injection volumes to achieve the best area-wide production uplift.

This tool simplifies what would otherwise be a complex, iterative process involving manual analysis of each well's gas lift performance curve. By automating the generation of individual well optimization curves and combining them into a system-level optimization, the tool helps engineers:

- Prioritize wells with the highest incremental oil rate per unit of injected gas

- Plan efficient gas injection strategies within a gas supply limit

- Compare the impact of different gas availability scenarios on total production

Portfolio-wide Optimization

Think of this feature as a “portfolio optimizer” for gas lift — instead of maximizing just one well, you’re maximizing your entire field.

2. Prerequisites

Before using the Multi-Well Gas Lift Optimizer, ensure the following for each well:

- The well has been set up with the appropriate wellbore configuration.

- At least one configuration uses Gas lift as the selected Artificial Lift method. If the well is not a gas-lifted well it will be ignored by the optimizer.

- A valid Rates and Pressures source date must be selected during a period when the well is operating under Gas Lift.

These inputs are essential to generate accurate gas lift performance curves for each well.

3. Workflow Steps

3.1. Create a Multi Well Gas Lift Optimization

- Go to the Multi-well Gas Lift Opt module in the navigation panel.

- Click Add Multiwell Gas Lift Optimizer up to the right.

- Enter a preferred name for the analysis.

- Select which wells to add to the analysis

- Click SAVE.

- All steps are shown in the .gif above.

3.1.1. Shared Gas Lift Area

The "Add Shared Gas Lift Area" feature allows you to organize gas lift analyses by grouping wells that share common infrastructure, such as a compressor, flowline, or surface facility. This is especially useful when managing multi-well gas lift systems where wells are interdependent or influenced by shared equipment.

When creating a Multi-Well Gas Lift Optimizer, you can add the analysis to an existing shared area. You can also add any analysis to existing shared areas as needed. All steps are shown in the .gif above.

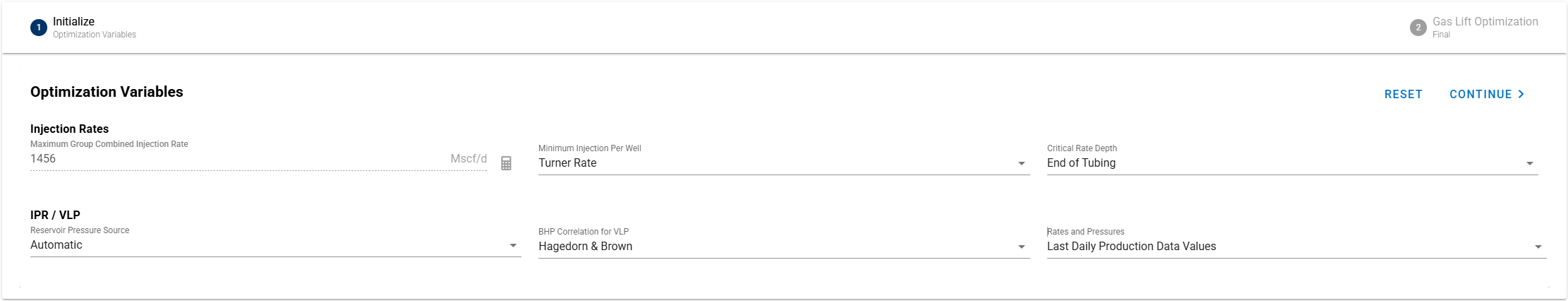

3.2. Initialize Optimization Variables

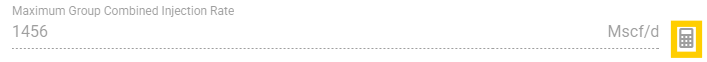

3.2.1. Maximum Group Combined Injection Rate

This input allows users to specify the maximum available gas injection rate for the group of gas-lift wells.

- Last Daily Aggregation of Group: uses the most recent daily total of gas-lift injection rates.

- Max Aggregation of Group from Prior X Days: uses the highest daily total of gas-lift injection rates over the past X days.

- User Defined Aggregate: allows manual input of the group's maximum combined injection rate. Useful for overriding automatic aggregation.

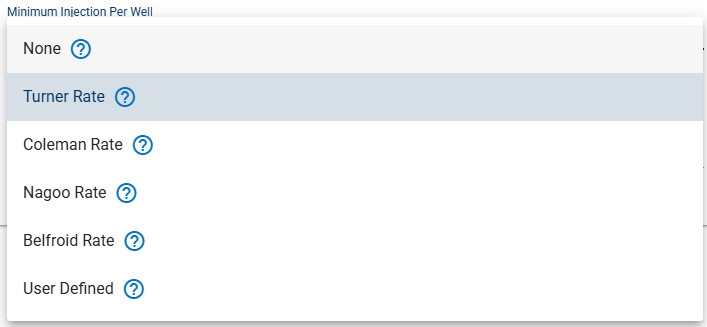

3.2.2. Minimum Injection per Well

This variable represents the minimum lift gas rate to use in the well. A value often used is the well critical gas rate required to prevent liquid loading.

- By default, the minimum gas injection rate is set using Turner correlation. Users can select a different correlation that best fits their analysis needs. In bhp and Nodal, the user can apply a correction factor to the critical rate for each well configuration. The same correction will apply to the critical rate value used here, if the same well configuration is used.

- Selecting None removes the minimum injection constraint entirely, allowing wells to become liquid loaded during the optimization run.

- Choosing User Defined enables users to manually specify a minimum gas injection rate that will be applied uniformly across all wells.

3.2.3. Critical Rate Depth

When using a correlation to calculate the minimum gas injection rate for each well, users can specify the point or depth along the well configuration where the critical gas rate should be evaluated.

- By default, the calculation is performed at the End of Tubing.

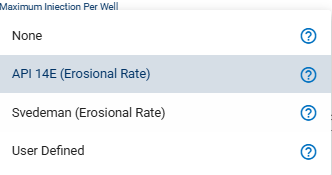

3.2.4. Maximum Injection per Well

This variable represents the maximum lift gas to use in the well. A value often used is the erosional gas rate.

- By default, the maximum gas injection rate is set using API 14E correlation. Users can select Svedeman & Arnold if that fits better their analysis needs (remember the Svedeman & Arnold model requires input sand rates). In bhp and Nodal, the user can apply a correction factor to the erosional rate for each well configuration. If the same well configuration/location is used in the optimization, the same correction will apply to the erosional rate value used here.

- Selecting None removes the maximum injection constraint entirely, allowing wells to become liquid loaded during the optimization run

- Choosing User Defined enables users to manually specify a maximum gas injection rate that will be applied uniformly across all wells.

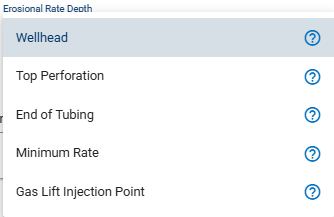

3.2.5. Erosional Rate Depth

When using erosional rate as the maximum gas injection rate for each well, users can specify the point or depth along the well configuration where the erosional gas rate should be evaluated.

- By default, the calculation is performed at the Wellhead.

Maximum Injection Rate Smaller Than Minimum Rate

There could be some situations when the "maximum injection per well" value is below the "minimum injection per well value". This could happen, for example, when using user defined "maximum injection per well" and Turner for "minimum injection per well" If this happens, the optimizer will set the well to the "maximum injection per well" value.

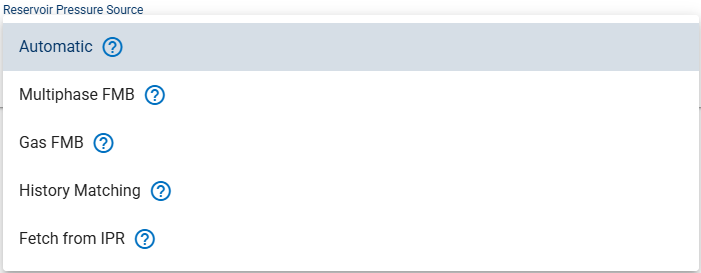

3.2.6. Reservoir Pressure Source

The Reservoir Pressure Source is used to generate the IPR/VLP curves and determine their intersection, which defines the operating point for gas-lifted wells.

- By default, Automatic is selected, meaning the reservoir pressure is sourced from the average reservoir pressure calculated in the Flowing Material Balance module for each well.

- History Matching uses the average reservoir pressure from the simulation results in the Numerical Model module.

- Users may also choose Fetch from IPR if they have manually generated IPR/VLP curves for each well in the Nodal Analysis module.

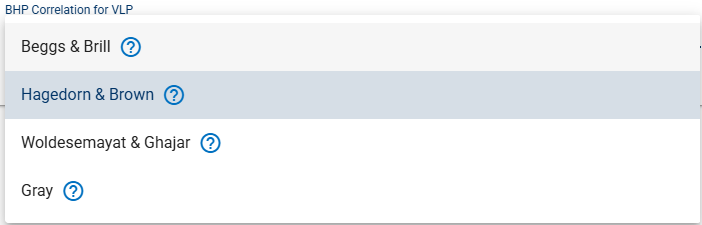

3.2.7. BHP Correlation for VLP

The selected BHP correlation will be applied universally to all wells, calculating BHP from the surface down to the top of perforation. This calculated pressure is then used to generate the VLP curve. The default correlation is Hagedorn & Brown.

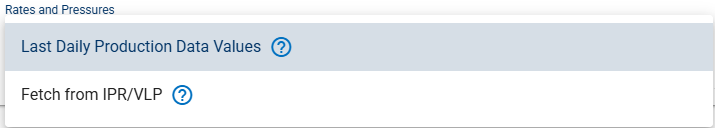

3.2.8. Rates and Pressures

The production data (rates and pressure) on a specific date is used to generate the IPR/VLP curves.

- Last Daily Production Data Values automatically selects the most recent available production data for each well.

- Fetch from IPR/VLP uses the values from manually generated IPR/VLP curves within the Nodal Analysis module for each well.

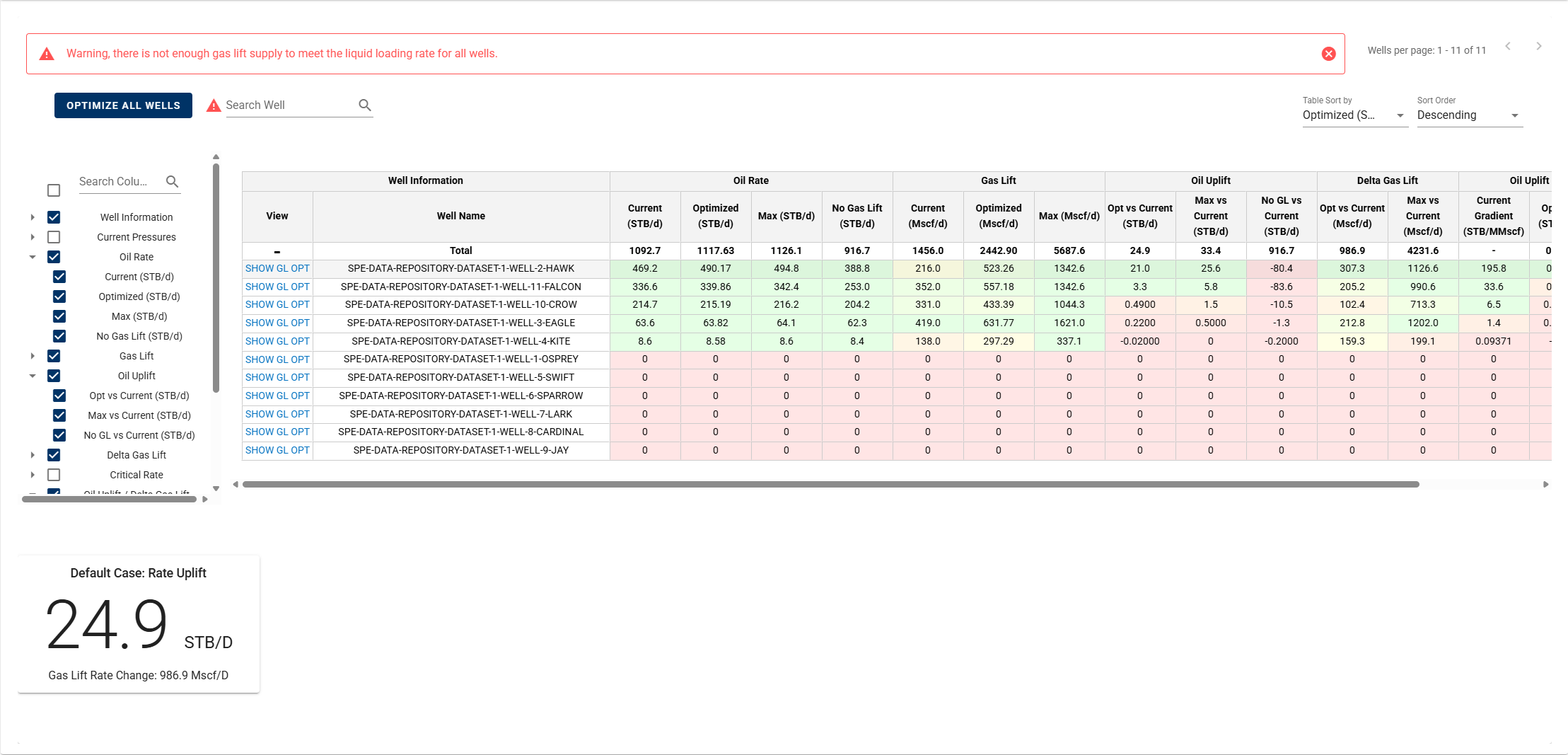

3.3. Optimize Multi-well Gas Lift

To run the multi-well gas lift optimization, click the OPTIMIZE ALL WELLS button (see figure below) and choose your preferred optimization option. The process will run shortly, and the results will be presented in a summary table.

-

Initialize and Optimize: This option considers all the parameters defined in the previous section (1. Initialize) before performing the optimization.

-

Optimize: This option will perform the optimization using the existing configuration set for each well.

4. Optimization Principles

The underlying principle of multi-well optimization is marginal uplift per unit gas injected. Wells that produce a steep increase in oil rate with a small increase in gas are prioritized over wells showing diminishing returns.

The optimizer follows these principles:

- Stage 1: Inject gas where marginal oil gain per Mscf is highest.

- Stage 2: Continue until the marginal gain drops or the gas limit is reached.

- Stage 3: Stop injecting when additional gas yields minimal or no production increase.

This avoids over-injecting gas into inefficient wells and ensures maximum field-level efficiency.

5. Example Case: Eagle Ford Wells

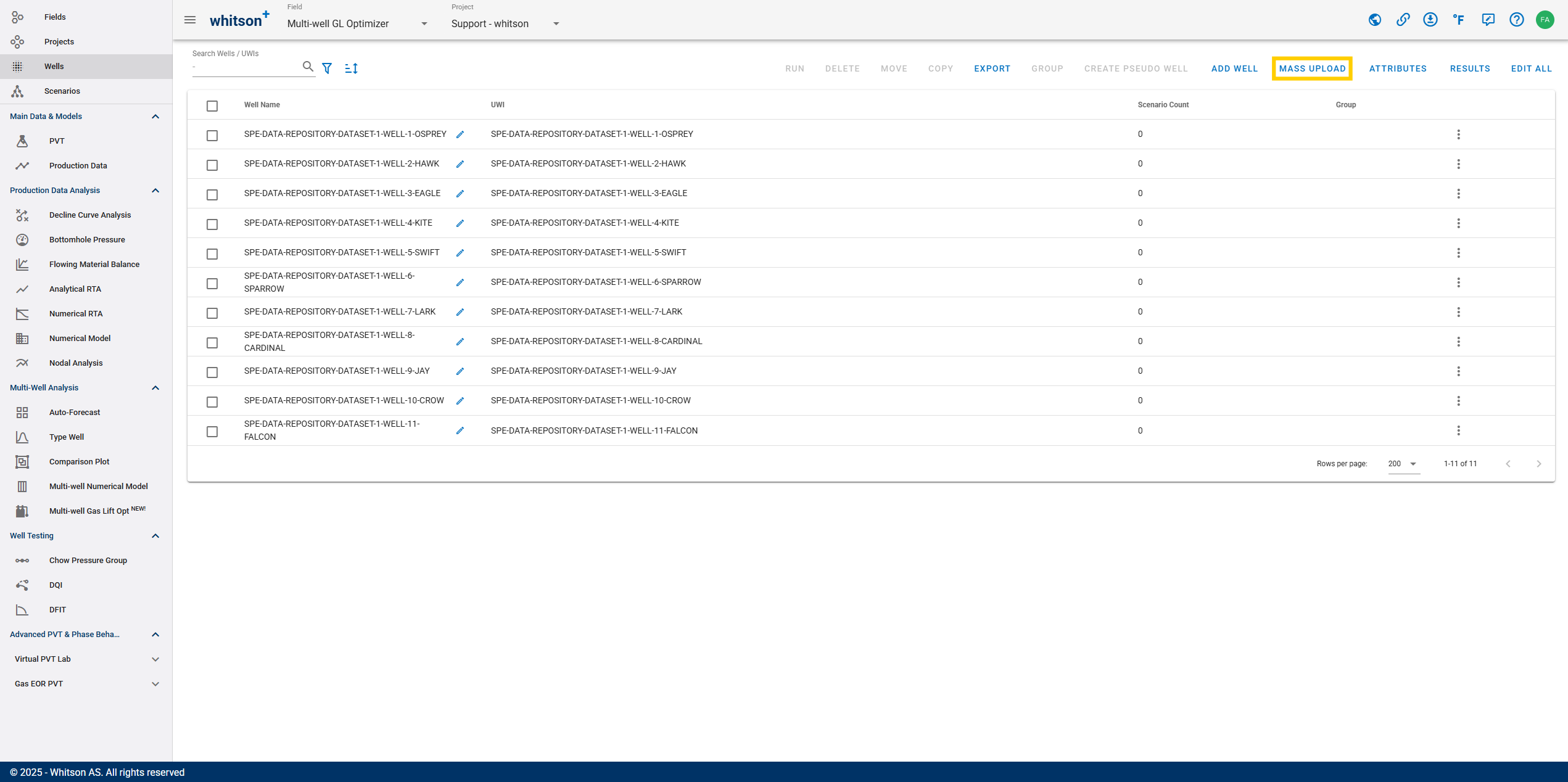

On a blank project, users can load the example wells using MASS UPLOAD -> EXAMPLES feature. This will load 11 wells into your project with production data and multiple artificial lift configurations, including Gas Lift.

Using Default Settings with Mixed Configurations

Not all wells have their last configuration as Gas Lift. This is an important reminder because we’ll use the default optimization setting, where rate and pressure values are pulled from the latest production data, which corresponds to the last configuration used in the well.

5.1. Initialize Optimization Variables

Once the wells are ready, navigate to the Multi-well Gas Lift Opt module from the left navigation panel, then proceed to create a new optimization scenario (click on ADD MULTIWELL GAS LIFT OPTIMIZER) and include all wells in this project. In this case, we use the default settings for the optimization variable initialization.

5.2. Multi-well Gas Lift Optimization Results

Once the multi-well optimizer has been created and initialized, navigate to the Gas Lift Optimization tab and click OPTIMIZE ALL WELLS to execute the optimization run. It will evaluate the optimal gas allocation for each well and display the results in a dynamic table.

Users can customize what outputs are shown by selecting the desired checkboxes in the parameter list on the left. We implement color scaling to help quickly identify performance across wells. In the bottom-left of the page, you'll see the "Total Current Oil Rate Uplift." This summarizes the total potential production gain from redistributing gas injection across wells.

Why Some Wells Show 0 Optimization Output

A value of 0 in the table indicates that the well was not optimized. This happens, in this case, because the well's last production data corresponds to a configuration that is not Gas Lift.